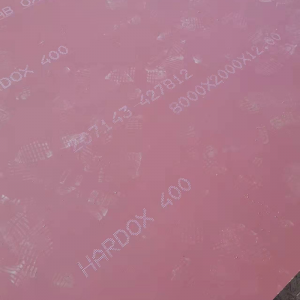

Detail

Kunyanya kushandiswa kwekunze kwesimbi inodzivirira simbi ndiro:

1) Michina yekuvaka nemidziyo: loader bulldozer excavator bucket plate, side blade plate, bucket bottom plate, blade, ndiro.

2) Kurodha uye kuburitsa michina nemidziyo: kuburitsa chigayo cheni ndiro, hopper lining plate, bati blade ndiro, yepakati-saizi otomatiki dump rori tipping ndiro.

3) Michina yekuvaka nemidziyo: simende pusher zino ndiro, kongiri yekuvhenganisa lining plate, kusanganisa pasi lining plate, guruva rekuunganidza lining plate.

4) Metallurgical michina nemidziyo: iron ore sintering inotakura gokora, iron ore sintering machine lining plate, scraper machine linening plate

5) Migodhi michina nemidziyo: lining plate yemigodhi muchina.

6) Mimwe michina yemuchina: jecha chigayo mbiya, blade, akasiyana kupfeka-anopokana zvikamu zvemichina yechiteshi.

7) Zvishandiso zvemagetsi zvinopisa: marasha chigayo lining board, marasha scutcher, marasha ekutumira pombi, marasha distributor ndiro, marasha ekuburutsa midziyo yekuisa bhodhi.

8) Shot blasting mechanical equipment: lining plate yepfuti inoputika muchina

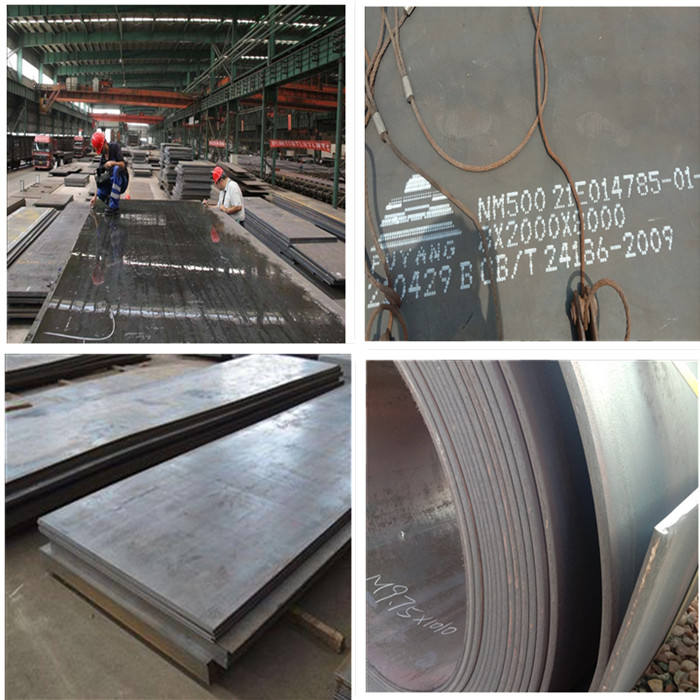

Kubva payakavambwa, kambani yanga iri kumhando yezvigadzirwa sekupona kwakakosha kwebhizinesi, kunaka kwesevhisi sezambuko rekubudirira kwedu isu tinotarisira nemoyo wese kumisa hukama hwebhizinesi nevatengi vedu, kupa sevhisi yemhando yepamusoro, nebhizimusi, common development.

Kuburikidza nekuenderera mberi kwekuvandudza, hunyanzvi, kuitira kuti nhanho yemhando yezvigadzirwa zvedu zvirambe zviri kumberi kweindasitiri yepamba.

Hunhu hunangwa: 98% yezvigadzirwa zvinopfuura yekutanga kuburitsa ongororo, 0.2% yezvigadzirwa zviri pamusoro zvinopfuura yekutanga kutakura yekuongorora kuwedzera gore negore, 100% yezvigadzirwa zvinopfuura fekitori.

"Kutendeseka, kutsvaga chokwadi, kusimudzira, hunyanzvi" ndicho chinangwa chebhizinesi chekambani yedu kwemakore mazhinji, gamuchira noushamwari ruzhinji rwevashandisi vesimbi isina tsvina uye vatinoshanda navo kuti vashanyire kambani yedu, nekuda kwekupfeka ndiro kugadzira inobwinya.

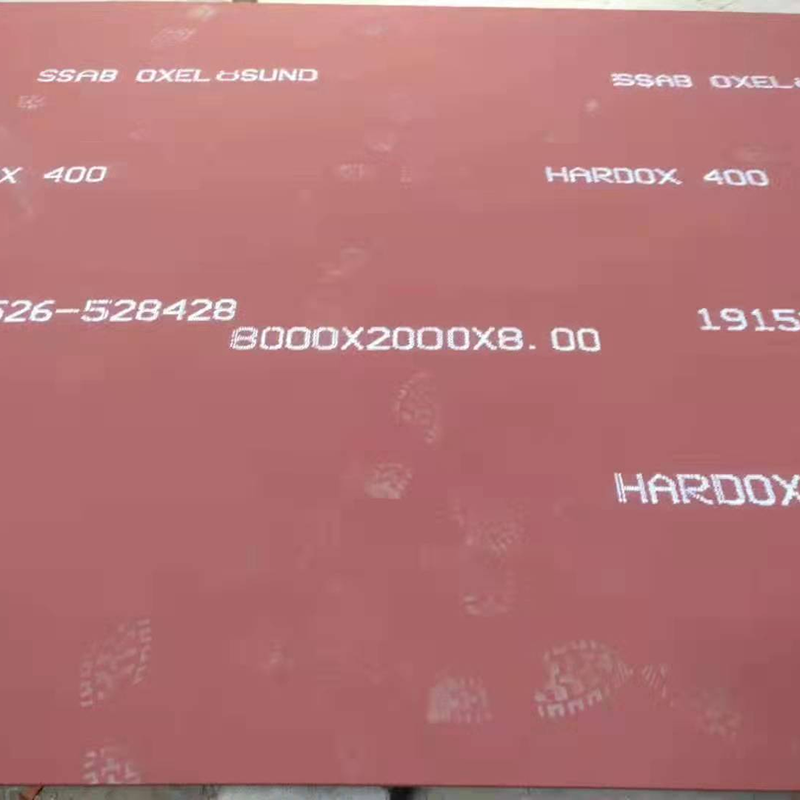

Ndiro yesimbi isingapfeki

| Giredhi | NM360/NM400/NM450/NM500/RAEX400/RAEX450/RAEX500/NM360,BHNM400,BHNM450,BHNM500,BHNM550,BHNM600,BHNM650,NR4360ARD-0,NR4360,NR360,NR360,NR360,NR360,NR360-40 |

| Ukobvu | 3+3,4+4,5+5,6+4,6+5,6+6,8+4,8+5,8+6,8+7,8+8,10+4,10+ 5,10+6,10+7,10+8,10+9,10+10,10+20,12+4,12+5,12+6,12+7,12+8,12+9, 12+1,12+11,12+12, 12+17,14+6,14+8,14+10,16+6,16+8,16+10,18+6,18+8,18+10,20+5,20+6,20+ 8,20+10,20+20,30+10,40+10, customized |

| Upamhi | 1500/2000/2500/3000MM |

Zvimwe Zvigadzirwa

1. Yakanakisa kupfeka kurambaIyo kemikari yealloy kupfeka-resistant layer ine kabhoni ye4 kusvika 5% uye chromium yemukati ye25 kusvika 30%.Iyo vhoriyamu chikamu cheCr7C3 carbides mune metallographic chimiro inopfuura 50%.Iyo macroscopic kuomarara iHRC56 kusvika 62. Kuomarara iHV1400~1800. Nokuti carbides yakagoverwa perpendicularly mugwara rekupfeka, kunyange kana ichienzaniswa neyakagadzirwa alloys yezvakafanana kuumbwa uye kuoma, kupfeka kuramba kunopfuura kaviri.Kuenzanisa nekupikiswa kwekupfeka kwezvinhu zvakati wandei ndeizvi: (1) Nesimbi yakaderera kabhoni;20~25:1 (2) Ne as-cast high chromium cast iron;1.5~2.5:1

2. Good impact resistanceChigadziko cheplate yesimbi inodzivirira kupfeka inogadzirwa nesimbi yakaderera kabhoni simbi kana yakaderera alloy.Zvinhu zvakaoma sesimbi isina tsvina zvinoratidza hukuru hwebimetal.Iyo yekupfeka-inodzivirira layer inopesana nekupfeka kwepakati pekupfeka, uye iyo substrate inotakura mutoro wepakati, saka ine yakanaka kukanganisa kupikisa.Inogona kumira nekukanganisa uye kupfeka kweiyo yakakwira yekudonha hopper mune inotakura zvinhu system.

3. Good heat resistanceIyo alloy kupfeka-resistant layer inokurudzirwa kushandiswa pasi pe ≤600 ℃.Kana vanadium, molybdenum uye mamwe maalloys akawedzerwa kune alloy kupfeka-resistant layer, inogona kumira kupisa kwekushisa kwe ≤800 ℃.Iyo inokurudzirwa tembiricha yekushanda yakaita seiyi: Yakajairwa kabhoni simbi base plate inokurudzirwa kuti ishandiswe pasi pemamiriro ekushanda asingasviki 380 ℃;Low-alloy heat-resistant steel plate (15CrMo, 12Cr1MOV, etc.) substrates inokurudzirwa kushandiswa mumamiriro ekushanda asingasviki 540 ℃;Iyo substrate yesimbi inodzivirira kupisa inokurudzirwa kuti ishandiswe isingadarike 800 ° C.

4. Good corrosion resistanceIyo alloy layer yekupfeka-inodzivirira composite simbi ndiro ine yakakwira muzana yesimbi chromium, saka ine imwe dhigirii ye ngura uye marara kuramba.Inogona kushandiswa kudzivirira kunamatira kwemarasha kana ichishandiswa mumadhiramu ekudonhedza marasha uye hoppers.

5. Pedzisa marudzi uye tsanangudzoIyo inopfeka-inodzivirira simbi ndiro ine yakazara yakatarwa uye akawanda marudzi, uye yave yekutengeserana serialization.Ukobvu hwekupfeka-resistant alloy layer ndeye 3-20mm.Ukobvu hwesimbi inosanganiswa ndiro inokwana 6mm, uye ukobvu hahuna kuganhurirwa.Iyo yakajairwa-inodzivirira simbi ndiro inogona kupihwa 1200 kana 3800 × 12000mm, uye inogona zvakare kugadziriswa zvichienderana nehukuru hwemadhirowa zvichienderana nezvinodiwa nemushandisi.Mahwendefa esimbi asingapfeki zvino akakamurwa kuita marudzi matatu: akajairika mhando, inopesana-inodzivirira mhando uye yakanyanya-tembiricha mhando.Kuraira yakakwirira-kupisa kusapfeka-inodzivirira uye inokanganisa-inodzivirira inoumbwa nesimbi mahwendefa inofanira kutsanangurwa.

6. Yakanaka kugadzirisa kushandaIyo simbi inomira-inodzivirira ndiro inogona kutemwa, kukotama kana kuremerwa, kukwenenzverwa nekuroverwa, uye inogona kugadziriswa kuita zvikamu zvakasiyana-siyana zvinogona kugadziriswa nemahwendefa esimbi.Iwo akachekwa akapfeka-anodzivirira simbi mahwendefa anogona kukwenenzverwa-akasungwa muakasiyana einjiniya zvimiro zvikamu kana zvikamu.

7. Mabasa uye ZvimiroInogona kuve yakasungwa uye ine yakanaka kupfeka kuramba..